Aerostructures

MANUFACTURER OF COMPLEX AEROSTRUCTURES

With its dual portfolio of civil and military activities, POTEZ AÉRONAUTIQUE undertakes the design, manufacturing, and integration of metallic and composite aerostructure parts and assemblies, and also offers customer support.

As a Tier 1 and Tier 2 supplier, the group enjoys the trust of its historical partners and indeed the majority of the players who will shape the skies of tomorrow.

International recognition of the group’s expertise in the production of doors and exits has earned it the status of sole supplier of passenger doors for the DASSAULT FALCON range.

Our expertise

DOORS

AIRFOIL ELEMENTS

SECTIONS & FUSELAGES

EMPENNAGES

COMPLEX SUB-ASSEMBLIES

OUR OPERATION

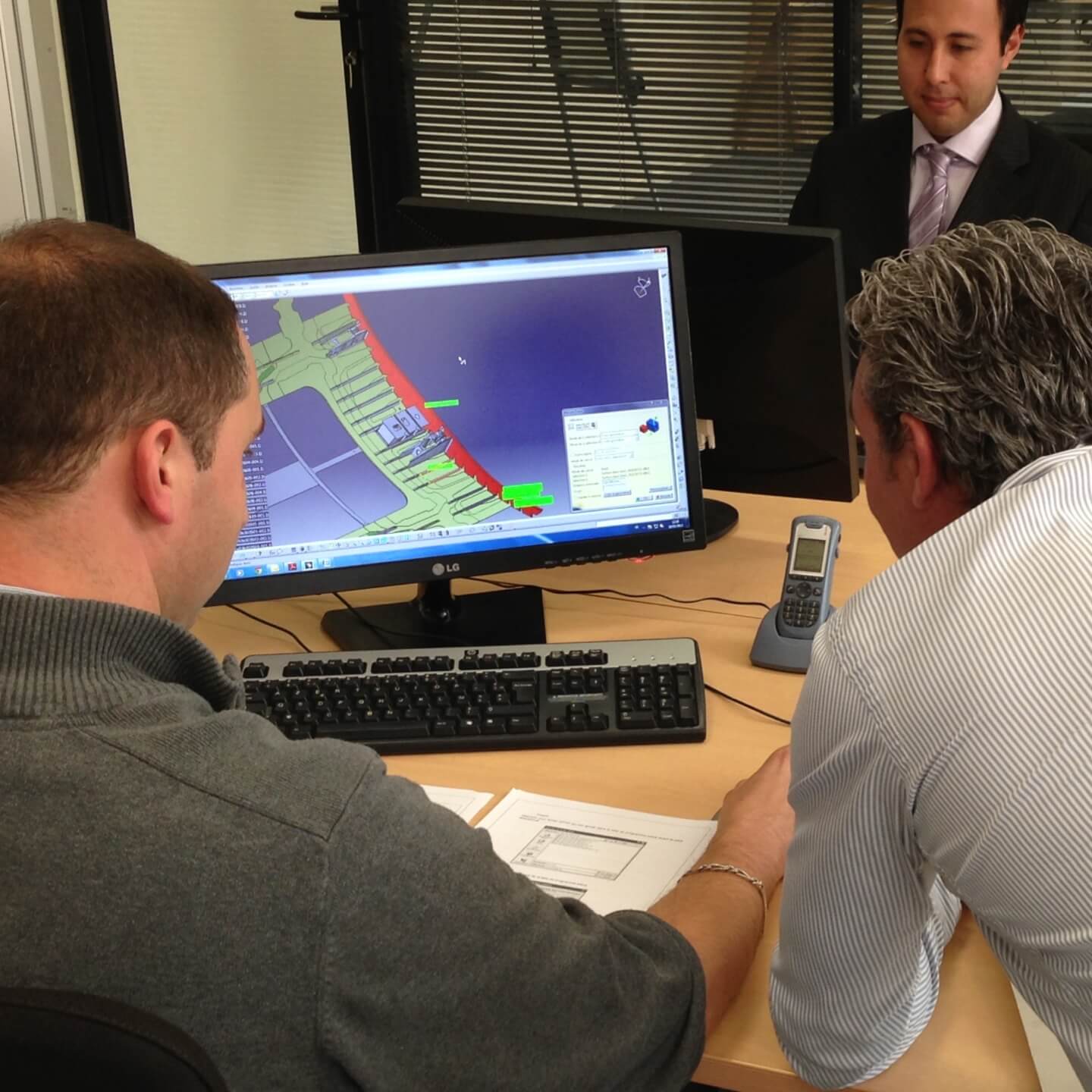

Design

Our skills in managing Design and Build projects from start to finish, with studies and calculations backed up by industrial know-how, offer our aeronautics clients a significant advantage in terms of efficiency, agility and creativity.

POTEZ AÉRONAUTIQUE benefits from widespread recognition by its clients who regularly turn to its experience for ambitious programs involving aircraft doors and complex aerostructure sub-assemblies.

The Group’s design activities include: feasibility studies, calculations, design, regulation and certification, testing, STC, exemptions, major modifications, STEE.

Industrialization

POTEZ AÉRONAUTIQUE’s capacity to rapidly implement new programs is a real asset for its clients.

Organization and methods departments play a pivotal role in balancing the client’s requirements with the constraints of production. Physically located in workshops that function as Autonomous Production Units (APU), these departments also participate fully in the processes of innovative projects. The teams use the latest technology such as 3D printing, which allows rapid prototyping, and the optimization of existing tooling lines. The group’s policy of continuously improving its industrial processes offers its teams unrivalled responsiveness. An example of this is designing, applying industrial techniques and ultimately manufacturing a complete set of doors in just 11 months.

Our processes to introduce industrial techniques involve design, the production of tools, configuration management and process engineering.

Detail parts

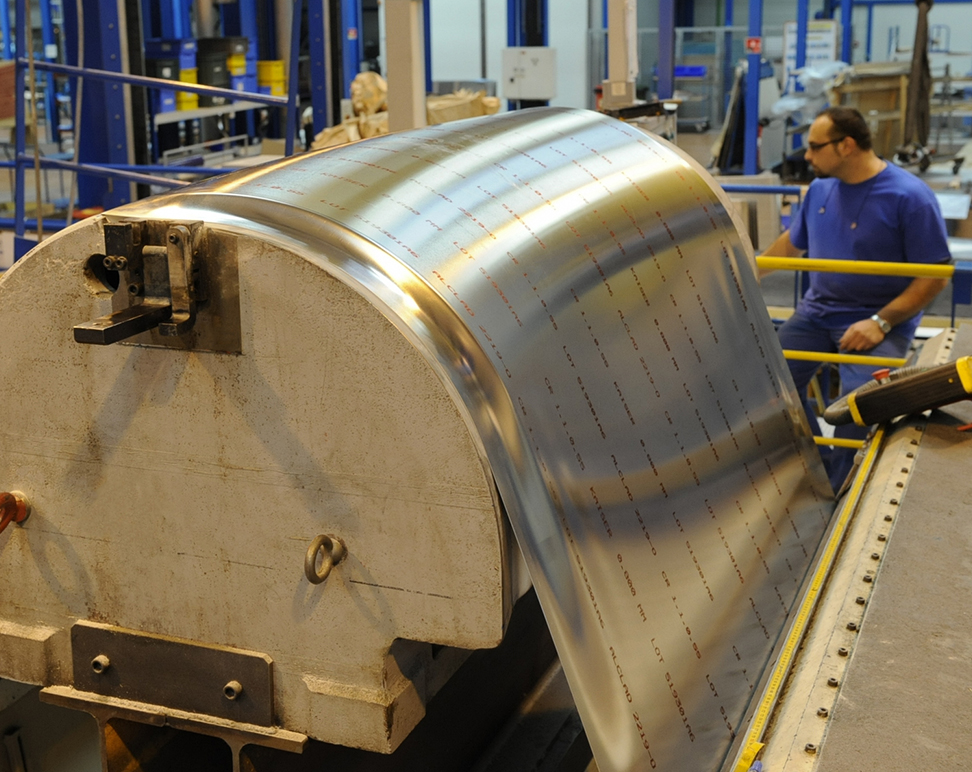

SHEET METALWORKING TO MANUFACTURE METALLIC ELEMENTARY PARTS

POTEZ AÉRONAUTIQUE is an expert in the manufacturing of sheet metal elementary parts, both large and small. The group’s mastery lies in counterforming and double curvature forming, in light alloys, stainless steel and titanium.

Equipped with substantial production resources and a range of special tools, the company is particularly recognized for its expertise in large-sized skins (4.5 m x 4 m) and profiles extursion stretch-forming.

MACHINING TO MANUFACTURE METALLIC ELEMENTARY PARTS

Our mechanical expertise allows us to complement our production line for sheet metal parts with our capacity to produce both complex mechanisms and structural parts (large frames), machined at high speed.

At the end of 2020, and as part of the France Relance plan, the Group accelerated its policy of investing in industrial technology by acquiring BRETON large-scale, high-speed, 5-axis machining centers.

COMPOSITE ELEMENTARY PARTS

Our ability to produce complex composite parts means that we can offer our clients mature solutions that act as alternatives and complements to metallic detail parts.

We specialize in lay-up processes using autoclave polymerization applied to monolithic or sandwich structures. These can be based on glass, aramid, or carbon fabrics pre-impregnated with phenolic or epoxy resins.

As leaders in the use of new thermosetting composites, we can meet the challenges of the new generation of aircraft by improving efficiency, economy, and eco-responsibility.

Furthermore, with the support of CORAC [French Civil Aviation Research Council], the Group is investing significantly in researching manufacturing processes for composite detail parts through the LRI (Liquid Resin Infusion) process. The aim is to optimize performance in terms of weight and cost.

Supply chain

POTEZ AÉRONAUTIQUE is convinced of the need to take control of the entire supply chain in order to be able to meet our commitments in terms of quality, cost, and delivery.

Consequently, we have established a strict monitoring policy for our suppliers.

The group has also invested heavily in its own logistical and industrial capacities in order to improve efficiency and competitiveness.

Assembly

Since its beginnings, POTEZ AÉRONAUTIQUE has possessed all the skills needed to assemble complete elements and complex aerostructures.

The operations range from frame assembly to production of fully equipped, pressurized fuselages. Our expertise includes the installation of all types of fittings, wiring installations and pressurization tests.

Never ceasing in its quest for operational excellence, POTEZ AÉRONAUTIQUE is involved in several innovative projects on assembly processes every year. In particular, this can take the form of the robotization of processes, robotics, digitalization, and the automation of control operations.

Fuselage equipment and wiring

POTEZ AÉRONAUTIQUE has added a new string to its bow with fuselage wiring.

A development that has allowed it to upgrade its know-how in complex fuselage assembly. The Group’s new expertise ranges from the installation of electrical and hydraulic mechanisms to power cabling and wiring harnesses.

We deliver complete, tested sections ready for installation.

MOC, modifications, prototyping and client support

Our expertise in the design and manufacturing of complex aerostructure elements, combined with PART 21J, 21G and PART and FAR 145 approvals facilitate our interventions in repairs, the production of spare parts for current or discontinued units, and the modification of aircraft structures.

Through the framework of our Design and Build contracts, we also assist our clients in the Operations Support phase of the elements that we produce. This includes document management, drafting maintenance, repair manuals, etc.

Operational readiness offers

Modifications (design and manufacturing)

On-site

operations

Maintenance and Repair

Retro-engineering